Tamper-evident packaging has long been seen as a requirement for most food, beverage, pharmaceutical, nutriceutical, and cosmetic items for consumer confidence. There are a wide array of existing tamper evident technologies in the packaging industry that you can take advantage of, such as tear away tamper evident bands on plastic closures, induction seal liners, and heat shrink bands. But recently decorative tamper evident labels have gained popularity as a way to provide a tamper evident feature to existing stock bottles and closures components without the need of component re-design while maintaining, or improving, shelf appeal.

Tamper Evident Closures

This is perhaps one of the most popular tamper indicating methods for plastic or glass bottles. It involves molding a tamper bead directly onto the bottle as it is being made. These types of designs accept caps and closures that are specifically designed to take advantage of this bead. Commonly referred to as tamper evident closures, these closures feature a tear away band that will literally "tear away" as the consumer loosens the cap. The exaggerated bead on the bottle will "catch" the tamper evident band, causing it to break away from the rest of the closure. Once the band has been broken, it drops to the bottom of the neck area, making it obvious to the consumer that the package has been previously opened.

This type of tamper evident package can be found in many dairy, water, and juice products. The downside of this approach is that the bottle components must be designed specifically to accept tamper evident closures. Modifying existing molds to accommodate tamper evident closures is possible, but can be cost prohibitive and time consuming.

Tamper Evident Liners (Such as Heat Induction)

The use of a liner system to provide tamper evident seals is also common, particularly in the dry food and pharmaceutical industry. These type of liners are often made with multiple layers of materials that, when sealed, will adhere to the land area of the bottle to create a seal. Consumers must break the liner in order to gain access to the product inside, and the liner material is designed not to reseal to the bottle once it has been removed, leaving behind evidence of prior entry.

Tamper evident liners are common and can be used with most stock plastic and glass packages. However, liner materials must first be tested to ensure proper adhesion with the bottle. Since the liner is a product facing material (it makes contact with the product), it must also be tested to ensure compatibility with the product itself. Further, special machinery is required to apply heat induction liners to ensure a proper seal.

Heat Shrink Band

Heat shrink bands come in all different sizes and must be measured specifically to a container and closure combination for optimal performance. Heat shrink bands are often perforated to help consumers remove the shrink band prior to use. However, since the heat shrink band does not actually adhere to the package, it may not work with all bottle designs such in cases where the closure sits flush along the side of the bottle, preventing the shrink band to “grab” onto the neck.

Commonly made with PVC plastic materials, heat shrink bands contract as they come in contact with heat (often a heat gun) and bind the closure and container together externally. The consumer would need to break the shrink band in order to remove the cap, and since it does not come in contact with the product inside, it is a popular option for many dry and liquid products in stock packaging that do not have the tamper evident bead.

Decorative Tamper Evident Labels

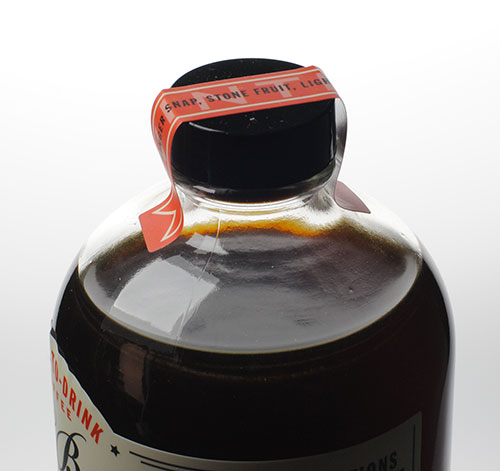

Decorative tamper evident labels have been gaining popularity recently with a wide range of industries, as they seek tamper evident options with existing packaging components, while enhancing their shelf appeal. These labels are often printed on paper stock or tamper evident stock, with decorative colors and designs that complement the package on the shelf.

Paper stock labels are often custom sized and shaped, adhered directly on the exterior of the closure and extend to the shoulder area of the bottle to bind the bottle and closure components together. Given the characteristics of paper stock labels, the labels will break easily when the closure is removed, thus achieving it's tamper evident purpose.

Tamper evident paper stock labels, common with the spirits and liquor industry and recently gained momentum in the cosmetic industry, take it a step further, it consists of a layer of materials that when peeled, will leave behind residue similar to some heat induction liners mentioned above, and will not reseal. Thus enhancing the tamper evident feature of the label that provides attractive sophistication to the presentation.