In packaging, aluminum reaches over 100 years as a mass-produced, commercialized material. What began as a niche material for the wealthy quickly unlocked possibilities that we take for granted today, including airplanes, lightweight automobiles, and space travel. Aluminum became a staple in the home and a cornerstone in the world's recycling stream for future generations when the beverage industry began developing the now commonplace soda and beer cans in the 1950s-1960s. There has never been metal in our early and contemporary society as influential as aluminum, touching many aspects of our daily lives, including packaging.

Aluminum is light and durable and contains various additional properties that make it the ideal material for containers! Let's learn more about this widely available metal and its relationship with packaging.

What is Aluminum?

As represented on the periodic table, Al, aluminum is the most abundant metal on the planet, making up about 8% of the earth's crust.

Pure aluminum does not exist independently because it can easily bind to other natural elements and must be extracted. The most popular form of aluminum in nature is derived from the rock bauxite.

Bauxite is broken down to aluminum oxide, where aluminum is refined and used in manufacturing bottles, cans, foils, and more.

It wasn't until the 19th century that electrolysis was used to obtain aluminum. Electrolysis involves electricity passing through matter to ignite a chemical change. This process can also be referred to as electrolytic reduction and is still used to get aluminum today.

Aluminum Packaging

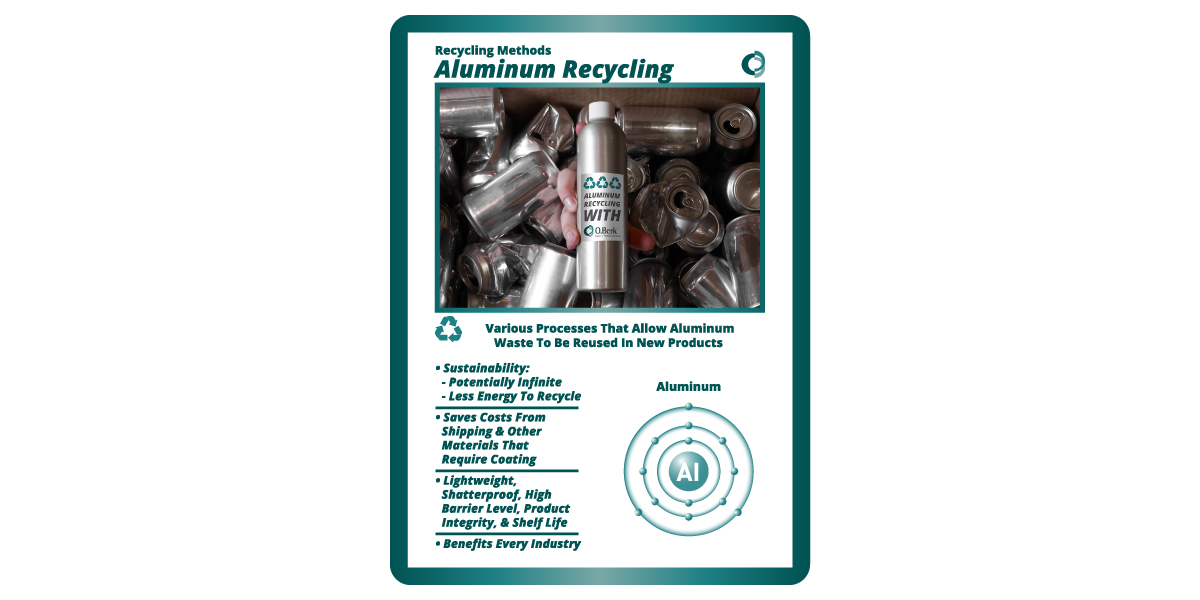

Aluminum is an ideal material for packaging due to its extended shelf life and low maintenance. It offers excellent barrier resistance to oxygen, moisture, and UV light to extend the product's lifespan. Aluminum is also shatterproof for the safety of the customer. New internal coatings allow us to offer Prop. 65 compliance with various products ranging from food and cosmetic use to chemical products such as bug repellants. These features make aluminum an optimum packaging material for beauty, personal care, and food and beverage markets.

As one of the lightest metals on earth, aluminum can help lower shipping costs, increase savings, and improve your overall bottom line. A decrease in the packaging weight can significantly impact cost savings when logistics are factored into shipping products from point A to point B.

There are extra cost savings for those in the food and beverage industries thanks to aluminum's protective barrier level. Other packaging materials require multiple layers, coatings, and costs to establish the same product integrity as aluminum because it's strong despite being thin.

The Process

Steps involved in aluminum recycling vary from facility to facility but often include:

- Hammering The Waste

- Manually Sorting

- Magnetizing Out Other Metals

- Shredding Into Smaller Pieces

- Filtering Out Small Bits To Unify Size

- Using X-Rays To Detect Alloys

- Removing Alloys With Air Jets

- Melting The Remaining Aluminum Into Blocks For Future Products

Watch our video above for a visual representation of these processes and how the aluminum blocks are used to create new bottles!

Recyclability and Sustainability

Over the last decade, the big trend in packaging has been providing sustainable, recyclable packaging solutions - an area where aluminum is a choice material.

Aluminum can undergo the recycling process repeatedly while maintaining its integrity with no performance or physical degradation. Since the aluminum industry first began, about 75% of the aluminum from its early beginnings is still used in today's markets - a sign of its longevity in recycling.

All internal coatings, external decorations, and traces of the former product's contents are removed during the recycling process.

On average, aluminum cans in the United States are composed of 68% recycled material, while globally, the recycling rate for aluminum cans is 69%. According to the Aluminum Association, it takes just 8% of the energy used to produce new aluminum to reintroduce recycled aluminum in the manufacturing process for newly finished parts.

Aluminum is at the forefront of sustainability and can help businesses position themselves with a competitive advantage due to its growing popularity and demand.

If you want to learn more about O.Berk's package offerings in aluminum, click here and let us get your next packaging project off the ground with a sustainable, attainable, recyclable, and reliable aluminum package.

View our online catalog of aluminum

here and save our trading card cheat sheet below for a quick reference on the benefits of aluminum recycling.

References

All About Aluminum: What Is Aluminum?

What Is The Most Abundant Metal On Earth?

6 Reasons Why Aluminum is the Perfect Material for Food Packaging

Reuter: FactBox: Aluminum cans get boost from anger over plastic pollution