Since its discovery, in the early 19th century the poise (P) has been used as the unit of measurement for viscosity. It has contributed significant advancements in product manufacturing, particularly in food, personal care, and pharma. Essentially without poise how would we be able to ensure products like toothpaste, shampoo, and ketchup flow properly into and out of glass and plastic containers? But how do you measure a product’s viscosity to get it just right?

Viscosity

First, we need to understand what viscosity is. It can be simply described as a fluid’s resistance to flow at a given rate. Another way to look at it is liquid as being thick (heavy) or semi-fluid (light) in its consistency. Products like motor oil, petroleum jelly, and hand-sanitizer have obvious varying viscosity levels just by viewing the flow of the product within a container. The flow rates of these products are measured by using the commonly used unit of measurement, poise.

History

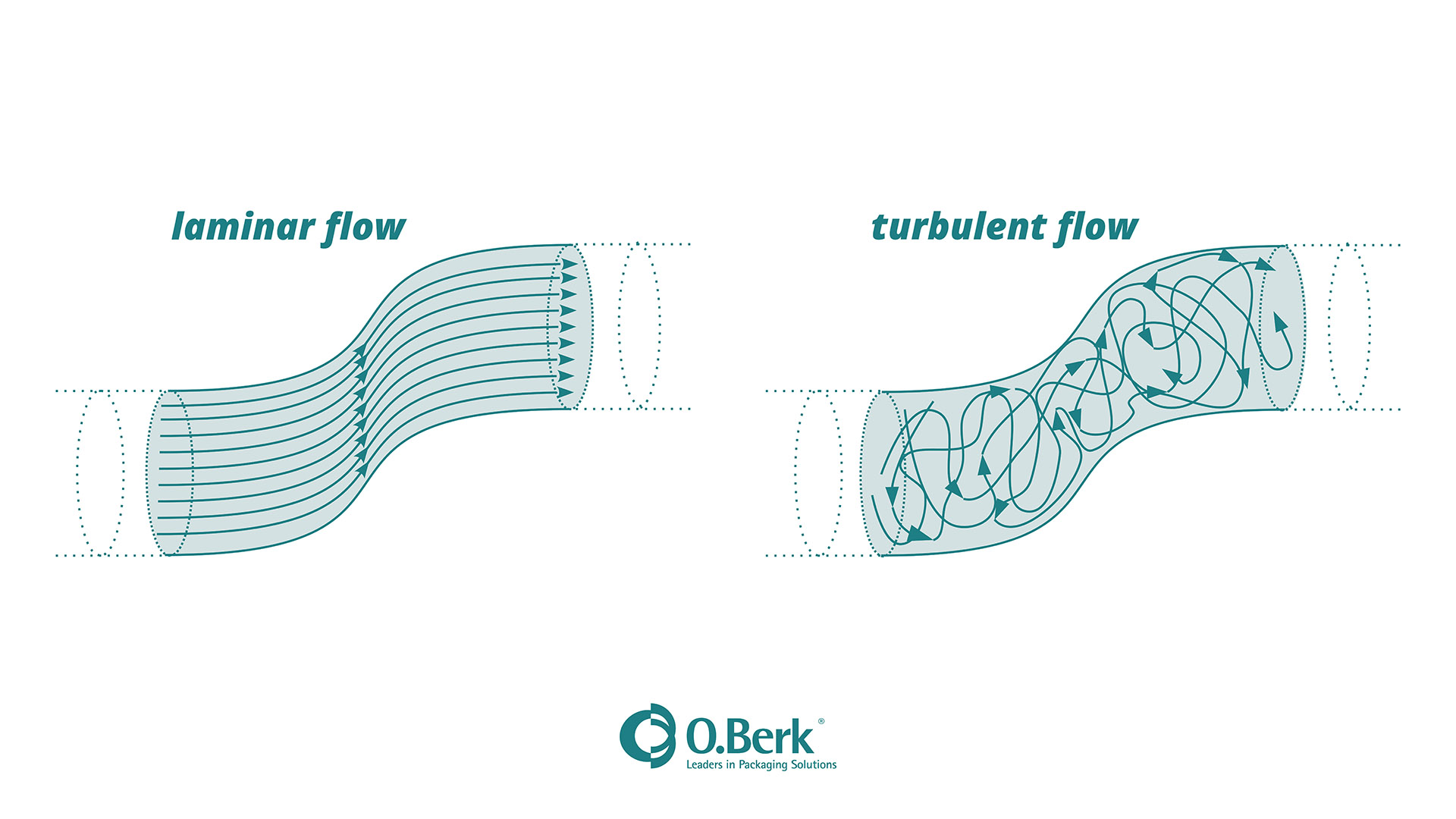

In 1829 a French physicist, Jean Louis Marie Poiseuille, founded the concept of measuring viscosity and for whom the unit was named after. He formulated the mathematical expression for the rate of flow for the laminar flow (non-turbulent flow) or to explain it in a formula:

Viscosity = shear stress / shear rate

- Shear Stress - force tending to cause deformation of a material by slippage along a plane or planes parallel to the imposed stress.

- Shear Rate - the rate of change of velocity at which one layer of fluid passes over an adjacent layer.

The result from the formula is often expressed as centipoise and commonly abbreviated as cP (one-hundredth of a poise). The metric prefix centi- is commonly used with poise because the viscosity of water at 20 degrees centigrade, under normal temperature and pressure, is near the equivalent of 1 poise.

The table below is an easier way to view the conversion P to cP:

- 1 poise to cP = 100 cP

- 2 poise to cP = 200 cP

- 3 poise to cP = 300 cP

- 4 poise to cP = 400 cP

- 5 poise to cP = 500 cP

- 6 poise to cP = 600 cP

- 7 poise to cP = 700 cP

- 8 poise to cP = 800 cP

- 9 poise to cP = 900 cP

- 10 poise to cP = 1000 cP

Click here to download our poise to centipoise conversion chart.

Testing

There are several ways to measure viscosity, or viscometers that are continuously in use with the following listing 4 procedures that have been developed:

Capillary Viscometer

This method is one of the earliest techniques for measuring viscosity involving the use of thin glass tubes to measure how long it took a volume of liquid to pass through it.

Zahn Cup

The Zahn Cup shares a similar style of measuring to the Capillary Viscometer but this method introduces a cup, resembling a thimble, with a hole at its base with an elongated handle. The time it takes for a volume of liquid to pass through the hole is recorded for measurement. Ink and paint industries utilize this method to measure the viscosity of their products.

Falling Sphere Viscometer

This method entails a sphere of a noted density that is dropped into a fluid sample in which the time it takes to reach a certain point is recorded. This widely used viscosity measurement method encompasses a variety of industries covering fuel, pharmaceutical reconstitutes, and condiments.

Vibrational Viscometer

A vibrating rod is submerged into a fluid sample where the vibrational waves are measured. Viscosity is determined by calculating the dampening of the vibrations. These instruments are often utilized for lab equipment and industries ranging from food & beverage to dyes and lacquers.

In closing, the measurement of viscosity is highly important in industry and its commonly used unit of measurement, the poise, plays into the daily processes of manufacturing foods, beverages, mechanical fluids, bio-pharma, and various other industries. Methods to measure and record viscosity levels have been created as early as the 1800s to take accurate measurements to produce the right consistency and rate of flow for products and their applications.

Works Cited

"Different Ways to Measure Viscosity." Rheosense.com. 13 March 2018. Web. 01 September 2020.

"Viscosity measurements in food products and manufacturing." newfoodmagazine.com. 27 October 2014. Web. 03 September 2020

"Viscosity Testing: Testing the Flow Properties of Liquid Products." cscsientific.com. Web. 08 August 2020.

"Converting poise to cP - Conversion of Measurment Unit." convertunits.com. Web. 04 September 2020.