Advancements in rigid packaging are continuously pushing the industry to reach new benchmarks. One of the industry's foremost goals is to support the growing market for more sustainable plastic packaging through innovative solutions. At the core of this sustainability initiative is the need to incorporate more recycled plastics into the packaging we use in our daily lives.

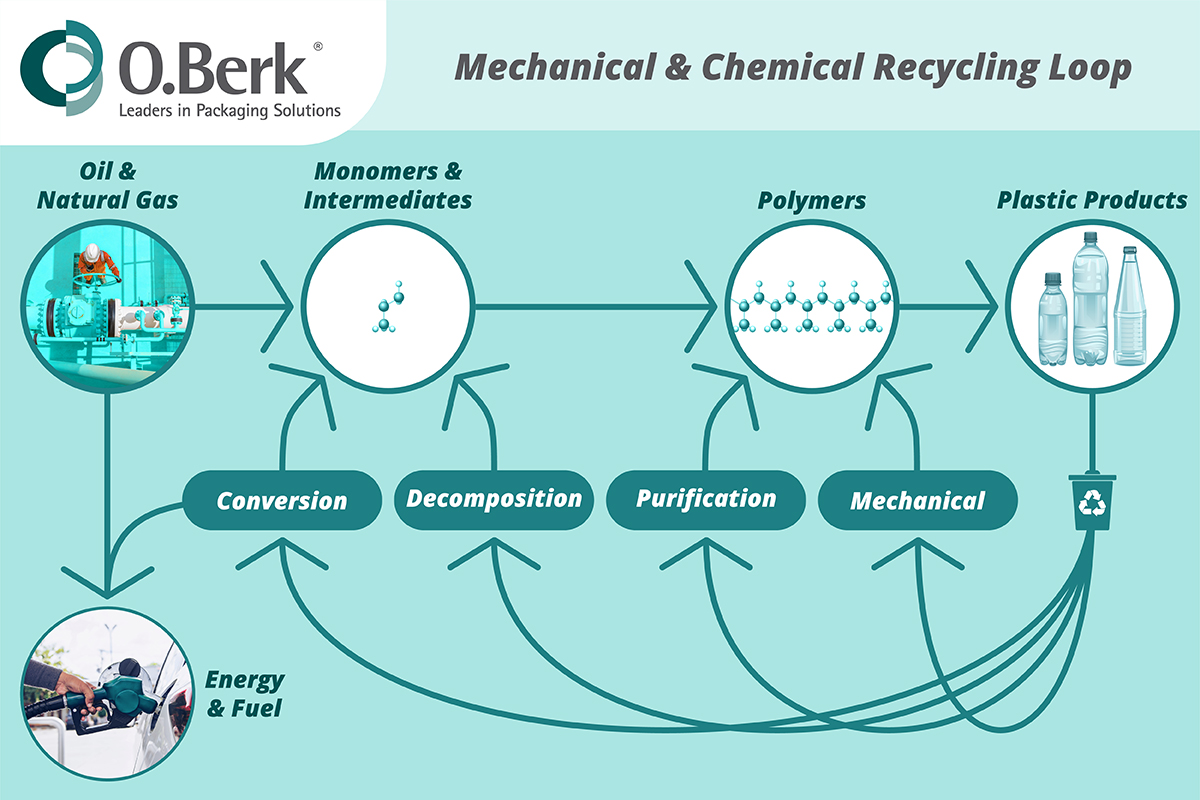

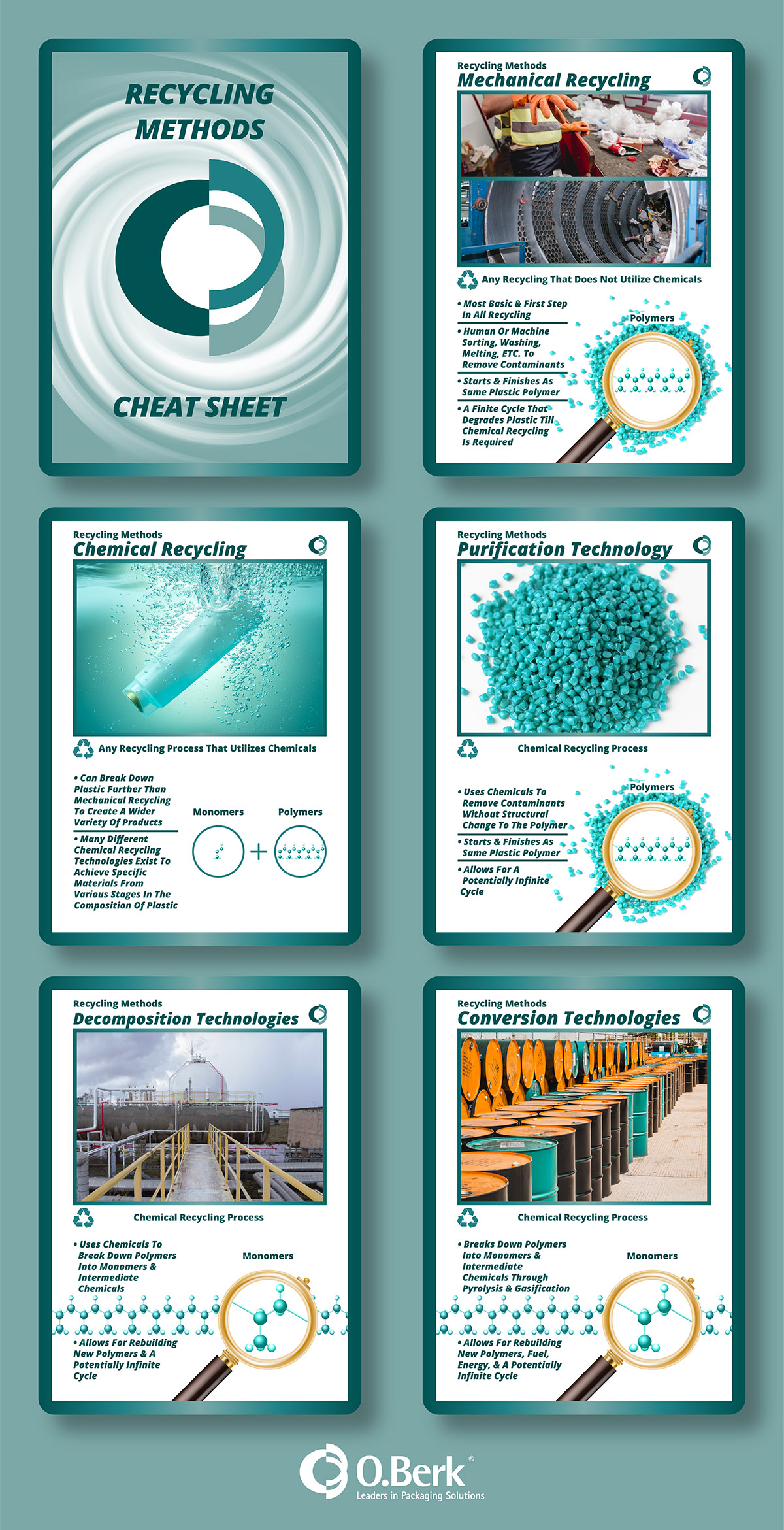

In today's Packaging Crash Course, we will cover two recycling methods and their distinct processes that enable us to provide sustainable solutions: Mechanical and Chemical Recycling.

Mechanical Recycling

When we bring up the term "recycling," we often refer to the widespread practice of collecting plastic waste from recycling bins or curbsides on collection day and then transporting it to a nearby recycling facility - the initial stages of mechanical recycling.

Mechanical recycling is a circular process where the same types of plastic materials undergo a rigorous sorting and cleaning process to eventually turn into the same flake or pellet feedstock from which they came. This feedstock will subsequently be used to create the same or similar finished plastic parts.

- Plastic Bottle >>>>> Plastic Bottle

- Plastic Bottle >>>>> Carpet

- Plastic Bottle >>>>> Auto Parts

For example, the input, plastic waste, can be a clear PET water bottle that goes through the mechanical recycling process, and the eventual output is another clear PET water bottle. An alternate result may be of a similar product, but the chemical makeup of the polymer/plastic remains unchanged.

Packaging that utilizes plastics that have undergone the mechanical recycling process is referred to as post-consumer resin (PCR). PCR is derived from post-consumer recycled content – mostly materials that have been recovered or diverted from your local municipal solid waste stream.

The mechanical recycling process includes multiple stages, including but not limited to conveyor belts, gravity, high propulsion air jets, washing, magnets, and manual human sorting of plastic components. The rigorous process helps to ensure the anticipated feedstock is free of any contaminants that can affect the integrity and performance of manufacturing new plastic parts.

The most common plastic materials recycled through the mechanical recycling process are PET and HDPE. These plastics can go through the recycling stream multiple times, but their lifespan is finite. Over time, these materials suffer degradation and loss of integrity, eventually rendering them useless. At this stage, a plastic can find new life in another recycling process - chemical recycling.

Chemical Recycling

Whether it is molecular recycling, transformation technology, or feedstock recycling, chemical recycling is a popular term currently passed around—a process of recycling that can apply various technologies to varying types of polymers (plastics).

To better understand the technologies, its best to note the different types of recycling technologies currently in use today:

Purification Technology

- Uses Chemicals To Remove Contaminants Without Structural Change To The Polymer

- Starts & Finishes As Same Plastic Polymer

Decomposition Technologies

- Uses Chemicals To Break down Polymers Into Monomers & Intermediate Chemicals

- Allows For Rebuilding New Polymers & A Potentially Infinite Cycle

Conversion Technologies

- Breaks Down Polymers Into Monomers & Intermediate Chemicals Through Pyrolysis & Gasification

- Allows For Rebuilding New Polymers, Fuel, Energy, & A Potentially Infinite Cycle

Chemical recycling technologies are paving the way for sustainable economies to thrive. Most plastics materials that undergo mechanical recycling processes repeatedly will find their properties degrade over time and cannot eventually maintain their integrity, losing the ability to perform their intended functions. That is when chemical recycling gives these degrading materials a new life.

The chemical recycling technologies mentioned earlier offer degraded and hard-to-recycle polymers a renewed purpose, literally. Some of these technologies can take single layer to mono-layer packaging, breaking it down to a molecular level for new building blocks. These building blocks can be used for fuels, chemical feedstocks, and new polymers akin to virgin resin integrity and performance in packaging.

Major resin suppliers in the chemical industrial sector have begun using chemical recycling technologies as recently as 2020. These technologies allow manufacturers to incorporate chemical recycling technologies alongside traditional coal-based and fossil fuel energy sources, helping reduce their dependence. In some cases, firms have ceased using conventional energy sources, and chemical recycling technologies have taken their place.

A conversion technology capable of converting plastic waste into fuel is pyrolysis. Pyrolysis consists of heating plastics at extremely high temperatures (approximately 300 degrees and 800 degrees Celcius) without oxygen present. Polymers are then broken down into organic compounds of hydrogen and carbon that can serve as feedstock for fuels. The output is an oil substance closely resembling crude oil, from which most plastics originate.

Utilizing mechanical and chemical recycling technologies and methods bring us closer to a sustainable economy. Through renewed practices of plastic waste management, we can increase the conservation of natural resources, enhance waste management to provide renewed energy sources, and positively impact the global quality of life.

For a quick reference on recycling methods, save our loop chart above and our cheat sheet below:

SOURCES:

Science & Tech Spotlight: Advanced Plastic Recycling

Sustainable Packaging Coalition: Mechanical Recycling Options

Henkel: Mechanical and chemical recycling of plastics | Henkel Circular Economy On The Go - Episode 7

Sustainable Packaging Coalition: The Essentials of Chemical Recycling

Eastman Chemical: Circular Solutions

Loop Industries

WWF - Sustainable Economies